Hlau Hlau Drawing Tshuab-Auxiliary Machinery

Kev them nyiaj

Hydraulic ntsug pay-off: Ob chav ntsug hydraulic pas nrig stems uas yooj yim rau xaim loaded thiab muaj peev xwm ntawm nruam hlau decoiling.

Kab rov tav them-tawm: Yooj yim them nyiaj nrog ob lub stems ua haujlwm uas tsim nyog rau cov xaim hluav taws xob siab thiab qis. Nws tuaj yeem thauj ob lub kauj ntawm tus pas nrig uas paub txog qhov txuas txuas txuas txuas txuas ntxiv.

Overhead pay-off: Passive type pay-off rau xaim coils thiab nruab nrog cov guiding rollers kom tsis txhob muaj cov hlau tsis zoo.

Spool pay-off: Lub cev muaj zog tsav them nyiaj nrog pneumatic spool kho kom ruaj khov hlau decoiling.

Hlau pretreatment khoom siv

Cov hlua hlau yuav tsum tau muab ntxuav ua ntej txheej txheem drwaing. Rau qis carbon hlau pas nrig, peb muaj patented descaling & txhuam tshuab uas yuav txaus rau deg tu. Rau siab carbon hlau pas nrig, peb muaj fumeless pickling kab los ntxuav tus pas nrig nto zoo. Tag nrho cov khoom siv pretreatment tuaj yeem ntsia tau rau hauv kab nrog lub tshuab nqus tsev lossis tuaj yeem siv sib cais.

Muaj kev xaiv

Roller descaling & Txhuam tshuab:

Xuab zeb siv descaler

Fumeless pickling kab

Coj-ups

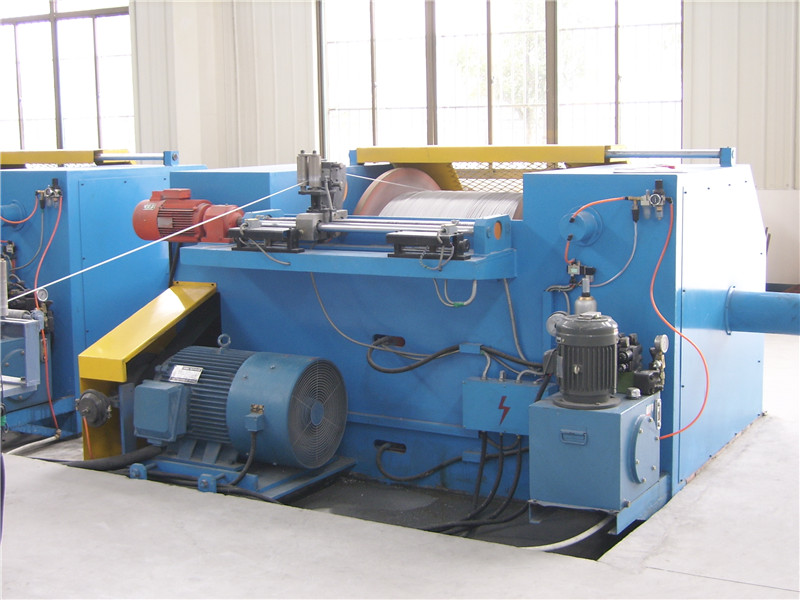

Coiler: Peb tuaj yeem muab cov txheej txheem ntawm cov kab tuag thaiv coiler rau ntau qhov sib txawv ntawm cov hlau. Peb cov coilers yog tsim los ua cov qauv ruaj khov thiab ua haujlwm siab. Peb kuj muaj turntable rau ntes hnyav coils kom tau raws li cov neeg siv khoom xav tau. Qhov txiaj ntsig ntawm kev siv cov duab kos tuag hauv cov txheej txheem kos duab yog tshem tawm ib qho thaiv ntawm lub tshuab nqus hlau. Rau coiling siab carbon steel hlau, lub coiler yog muab nrog tuag thiab capstan thiab nruab nrog nws tus kheej txias system.

Spooler: Spoolers ua haujlwm ua ke nrog cov hlau hlau kos duab thiab siv los nqa cov xov hlau txuas mus rau cov hlua khov. Peb muab kev sib txuas ntawm spoolers rau qhov sib txawv kos hlau loj. Lub spooler yog tsav los ntawm cais lub cev muaj zog thiab kev ua haujlwm ceev tuaj yeem ua ke nrog lub tshuab nqus tsev

Lwm lub tshuab

Lub taub hau welder:

● Siab clamping quab yuam rau cov xov hlau

● Micro computer tswj tsis siv neeg vuam & annealing txheej txheem

● Kev hloov kho yooj yim ntawm lub puab tsaig nyob deb

● Nrog kev sib tsoo chav thiab txiav ua haujlwm

● Annealing li rau ob qho tib si qauv muaj

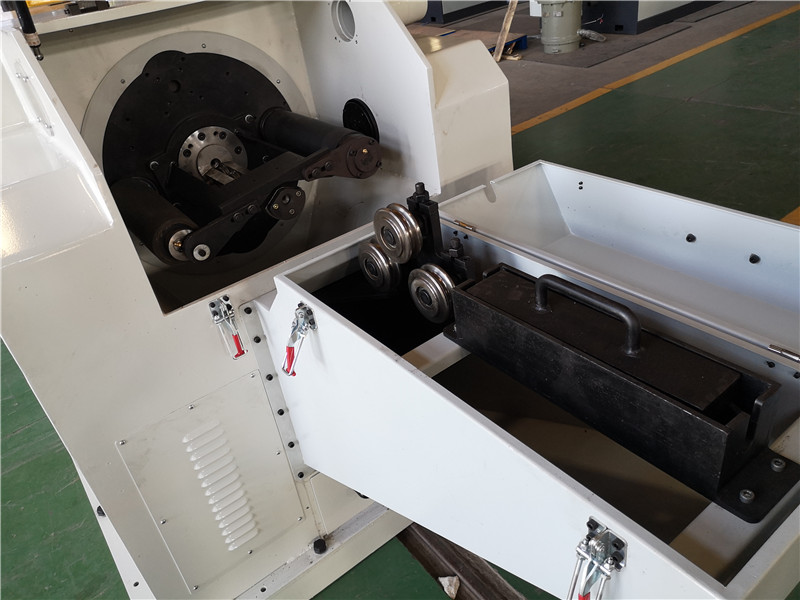

Hlau pointer:

● Rub-nyob rau hauv ntaus ntawv ua ntej pub hlau pas nrig hauv ib kab kos

● Hardened rollers nrog lub neej ua haujlwm ntev

● Movable tshuab lub cev rau kev ua haujlwm yooj yim dua

● Lub cev muaj zog tsav tsheb rau cov menyuam