High-Efficiency Hlau thiab Cable Extruders

Cov cim tseem ceeb

1, saws zoo heev alloy thaum kho nitrogen rau cov ntsia hlau thiab chim, ruaj khov thiab ntev kev pab cuam lub neej.

2, cua sov thiab cua txias system yog tsim tshwj xeeb thaum lub sij hawm kub yuav tsum tau teem nyob rau hauv qhov ntau ntawm 0-380 ℃ nrog high-precision tswj.

3, tus phooj ywg ua haujlwm los ntawm PLC + kov npo

4, L / D piv ntawm 36: 1 rau kev siv tshwj xeeb cable (lub cev foaming thiab lwm yam)

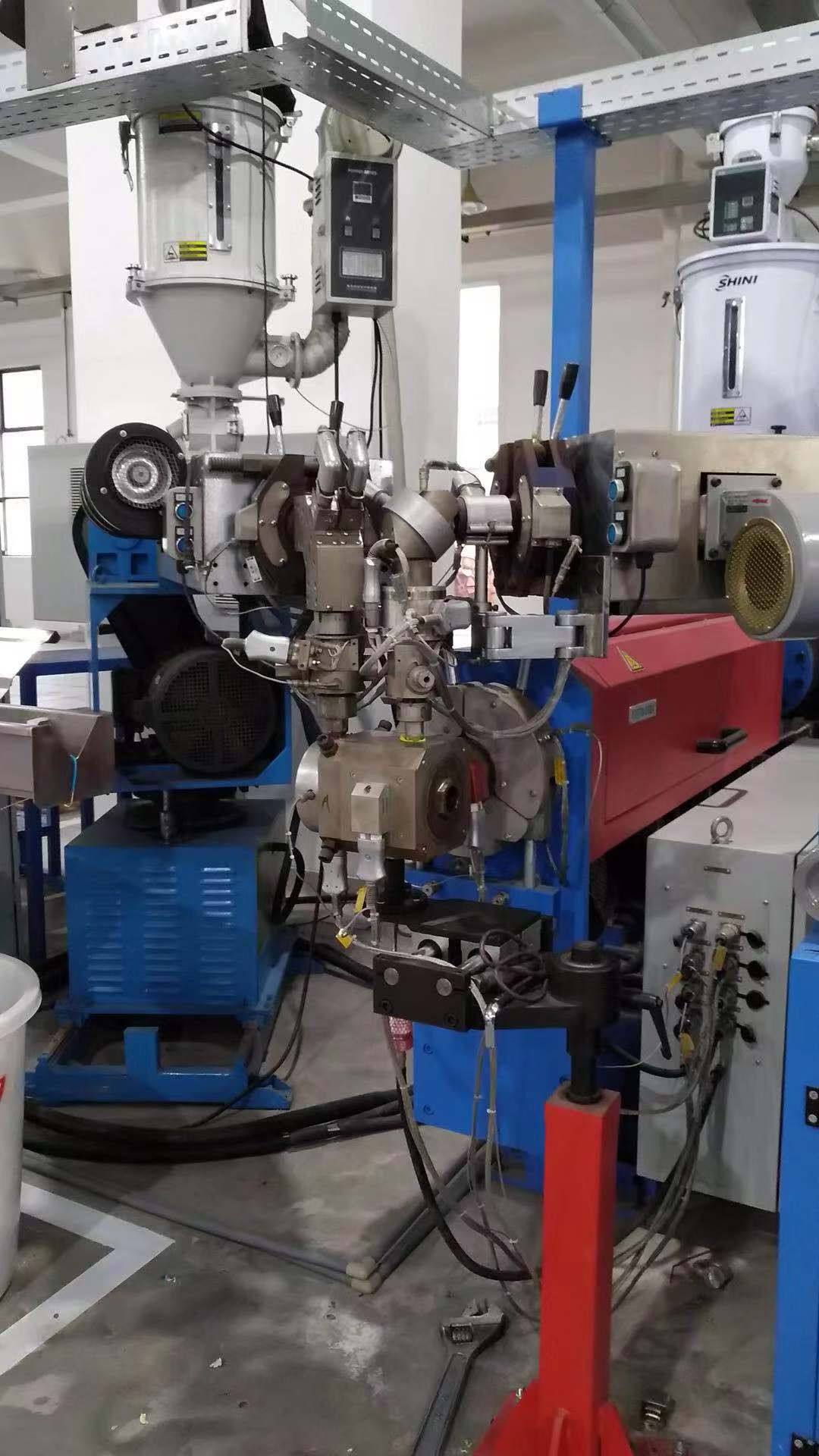

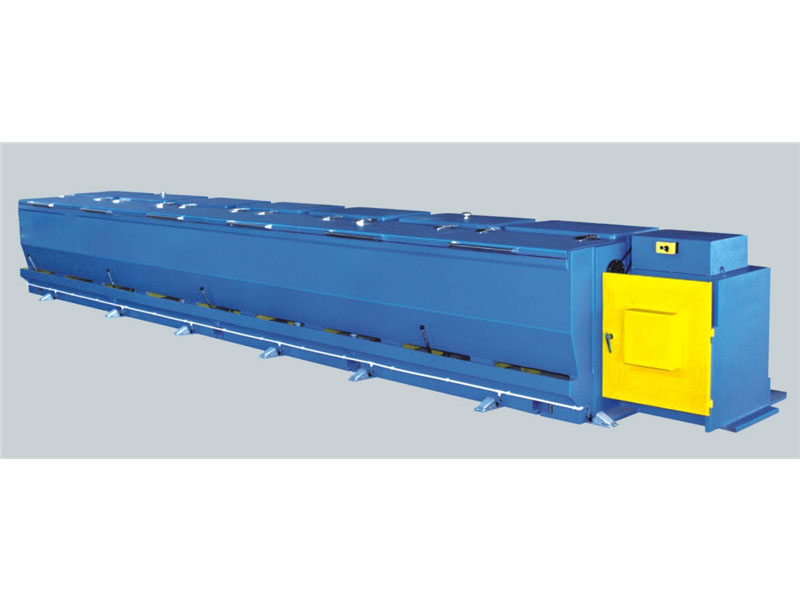

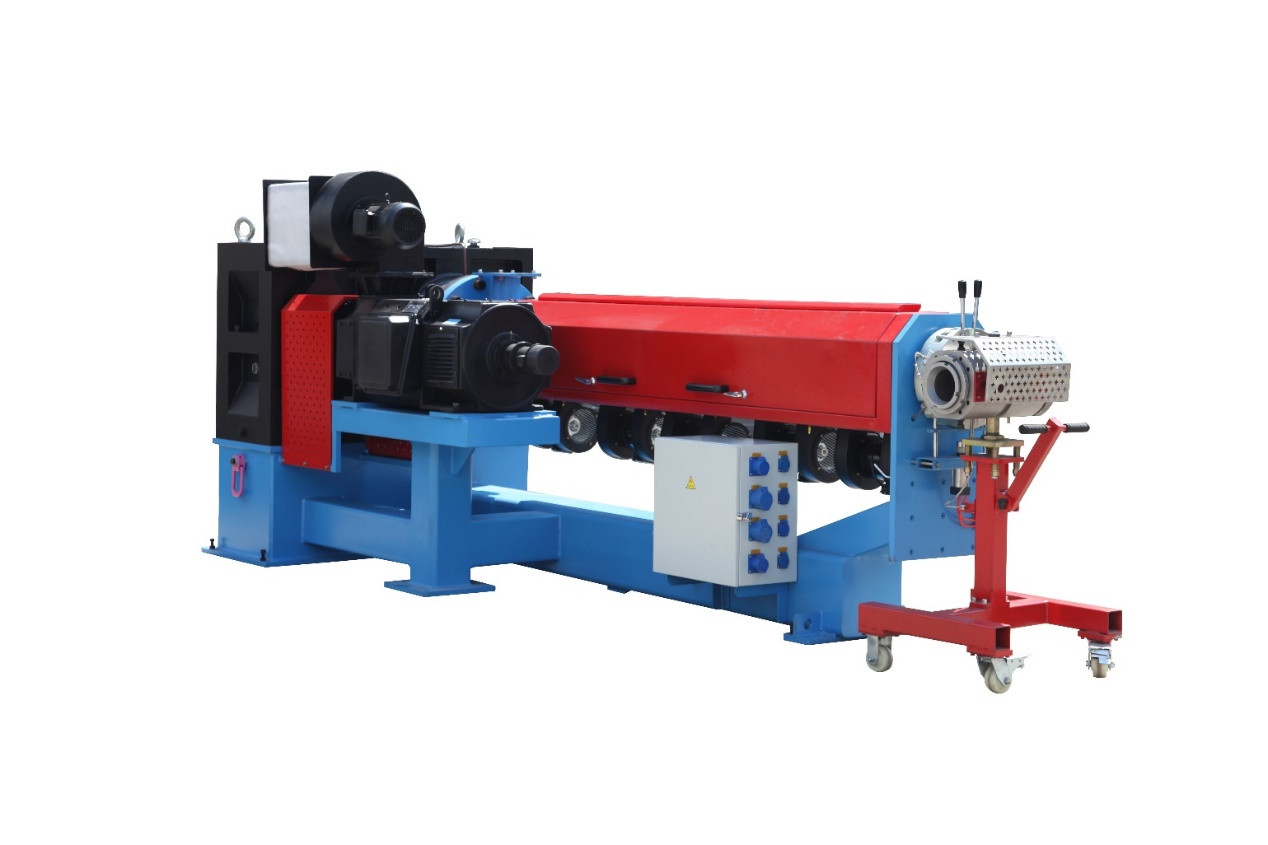

1.High efficiency extrusion tshuab

Daim ntawv thov: Feem ntau yog siv rau rwb thaiv tsev los yog sheath extrusion ntawm cov xov hlau thiab cables

| Qauv | Ntsia hlau parameter | Extrusion peev (kg / h) | Main lub cev muaj zog (kw) | Qhov hluav taws xob hlau dia.(mm) | ||||

| Dia.(mm) | L/D ratio | Ceev (rpm) | PVC | LDPE | LSHF | |||

| 30/25 ib | 30 | 25: 1 | 20-120 Nws | 50 | 30 | 35 | 11 | 0.2-1 |

| 40/25 ib | 40 | 25: 1 | 20-120 Nws | 60 | 40 | 45 | 15 | 0.4-3 |

| 50/25 | 50 | 25: 1 | 20-120 Nws | 120 | 80 | 90 | 18.5 Nws | 0.8-5 |

| 60/25 | 60 | 25: 1 | 15-120 : kuv | 200 | 140 | 150 | 30 | 1.5-8 |

| 70/25 ib | 70 | 25: 1 | 15-120 : kuv | 300 | 180 | 200 | 45 | 2-15 |

| 75/25 ib | 75 | 25: 1 | 15-120 : kuv | 300 | 180 | 200 | 90 | 2.5-20 |

| 80/25 ib | 80 | 25: 1 | 10-120 Nws | 350 | 240 | 270 | 90 | 3-30 |

| 90/25 ib | 90 | 25: 1 | 10-120 Nws | 450 | 300 | 350 | 110 | 5-50 |

| 100/25 | 100 | 25: 1 | 5-100 | 550 | 370 | 420 | 110 | 8-80 |

| 120/25 ib | 120 | 25: 1 | 5-90 | 800 | 470 ib | 540 | 132 | 8-80 |

| 150/25 ib | 150 | 25: 1 | 5-90 | 1200 | 750 | 700 | 250 | 35-140 : kuv |

| 180/25 ib | 180 | 25: 1 | 5-90 | 1300 | 1000 | 800 | 250 | 50-160 : kuv |

| 200/25 | 200 | 25: 1 | 5-90 | 1600 | 1100 | 1200 | 315 | 90-200 Nws |

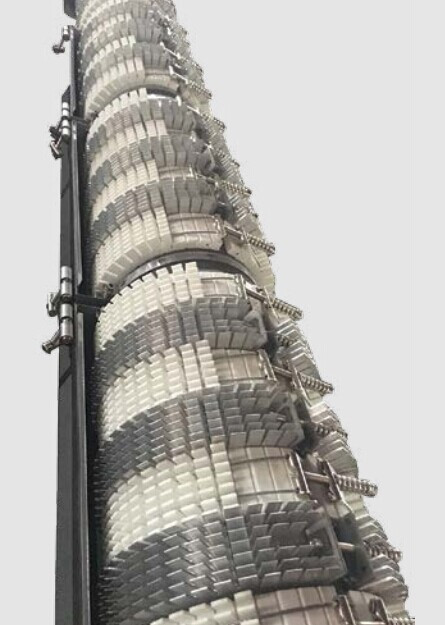

2.Ob txheej co-extrusion kab

Daim ntawv thov: Co-extrusion kab yog tsim rau cov pa tsis muaj pa halogen dawb, XLPE extrusion, feem ntau yog siv los tsim cov chaw nres tsheb hluav taws xob nuclear, thiab lwm yam.

| Qauv | Ntsia hlau parameter | Extrusion muaj peev xwm (kg / h) | Inlet hlau dia. (mm) | Qhov hluav taws xob hlau dia. (mm) | Kab ceev (m / min) | |

| Dia.(mm) | L/D ratio | |||||

| 50+ 35 | 50+ 35 | 25: 1 | 70 | 0.6-4.0 | 1.0-4.5 Nws | 500 |

| 60+ 35 | 60+ 35 | 25: 1 | 100 | 0.8-8.0 Nws | 1.0-10.0 Nws | 500 |

| 65+40 ib | 65+40 ib | 25: 1 | 120 | 0.8-10.0 Nws | 1.0-12.0 Nws | 500 |

| 70+ 40 | 70+ 40 | 25: 1 | 150 | 1.5-12.0 Nws | 2.0-16.0 Nws | 500 |

| 80+ 50 | 80+ 50 | 25: 1 | 200 | 2.0-20.0 Nws | 4.0-25.0 Nws | 450 |

| 90+ 50 | 90+ 50 | 25: 1 | 250 | 3.0-25.0 Nws | 6.0-35.0 Nws | 400 |

3.Triple-extrusion kab

Daim ntawv thov: Triple-extrusion kab yog tsim rau cov pa tsis muaj pa halogen dawb, XLPE extrusion, feem ntau yog siv los tsim cov chaw nres tsheb hluav taws xob nuclear, thiab lwm yam.

| Qauv | Ntsia hlau parameter | Extrusion muaj peev xwm (kg / h) | Inlet hlau dia. (mm) | Kab ceev (m / min) | |

| Dia.(mm) | L/D ratio | ||||

| 65+40+ 35 | 65+40+ 35 | 25: 1 | 120/40/30 ib | 0.8-10.0 Nws | 500 |

| 70+40+ 35 | 70+40+ 35 | 25: 1 | 180/40/30 ib | 1.5-12.0 Nws | 500 |

| 80+ 50+ 40 | 80+ 50+ 40 | 25: 1 | 250/40/30 ib | 2.0-20.0 Nws | 450 |

| 90+ 50+ 40 | 90+ 50+ 40 | 25: 1 | 350/100/40 | 3.0-25.0 Nws | 400 |